Fiber Glass Cloth Electrical Tape 560RS with Acrylic Adhesive for Transformers Banding

Overview Package Size 41.00cm * 27.00cm * 18.00cm Package Gross Weight 60.000kg Product Description This product is made

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | 560RS |

| Fiberglass Type | E-Glass |

| Alkali Content | Alkali Free |

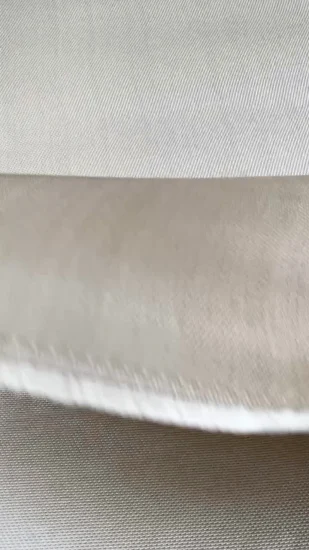

| Backing Color | White |

| Temperature Resistance | 155c |

| Thickness | 0.18mm |

| Adhesive | Acrylic Acid |

| Backing | Glass Fabric/ Cloth |

| Transport Package | Pallet |

| Specification | A Grade |

| Trademark | utek |

| Origin | China |

| HS Code | 7019909000 |

| Production Capacity | 100000/M |

Packaging & Delivery

Package Size 41.00cm * 27.00cm * 18.00cm Package Gross Weight 60.000kgProduct Description

Product DescriptionThis product is made of imported glass cloth coated with acrylic adhesive.It has the advantages of good temperature resistance, strong adhesion, strong toughness and tear resistance. It is mainly used in high-strength insulation protection such as H-grade heat-resistant insulation strapping, various high-temperature sandblast protection and lithium-manganese batteries insulation wrapping.

Composition

| Backing | Glass fabric |

| Adhesive | Acrylic acid |

| Backing Color | White |

Physical properties

| GB/T Test method | ||

| Adhesion (normal) | 2N/10mm | 2792 |

| Tensile strength | 200N/10mm | 7753 |

| Elongation at break | 4.5% | 7753 |

| Thickness | 0.18mm | 7125 |

| Electrical Strength (Normal) | 2000V | - |

| Temperature resistance | 155ºC | - |

Specification

| Standard width | 10mm | Customizable |

| Standard length | 33m | Customizable |

Characteristics

| 1.Good thermal stability, can work at 155 ºC, and can withstand high temperature of 180 ºC in a short time.2.Soft and tear-resistant, strong cohesion, not easy to deform, suitable for pasting protection on the surface of various profiles.3.No adhesive residue, no glue residue remains when the tape is removed after high temperature curing.4.High mechanical strength, suitable for tight and firm coil wrapping. |

| 1.The wrapping of the H-grade motor and transformer coil lead wires.2.High-energy lithium battery insulation wrapping.3.Induction furnace power supply, lead wires are electrically insulated.4.Repair of mine equipment, reinforced insulation. |

Operation Precautions

| 1.Clean the oil and dust from the bonding surface.2.Avoid repeated sticking (otherwise the adhesive surface of the tape will be damaged), and let it sit for a while after sticking.3.Apply enough pressure to reduce residual air from the tape and adhesive surface.4.In order to achieve better bonding effect, it is recommended that the best operating environment temperature range is 25-30 °C. |

Storage conditions

| 1.It is recommended to place it in a warehouse without volatile solvents with a temperature of -5 to 30 °C and a relative humidity of 40 to 60%.2.Avoid placing it where it is exposed to direct sunlight, rain and dust.3.In order to prevent the product from being deformed, try not to place it horizontally and be squeezed.4.Original packaging with a shelf life of 6 months from the date of shipment. |

Give us a chance, and we' ll return you with satisfaction.