Fiberglass/ High Silica/Surfboard Cloth/Chopped Strand Mat/Tissue/Surface Mat/Multiaxian Fabric/Twill Fiberglass

INTRODUCTION Chopped Strands are produced by cutting strand bundles, which are made of 50 to 200 fine ARG fiber filament

Send your inquiryDESCRIPTION

Basic Info.

| Function | High Strength Fiber |

| Transport Packing | Plastic Non-Woven Bag/Pallet |

| Certification | ISO/SGS |

| Tensile Strength | >2000MPa |

| Fibre Length | 3mm, 5mm,12mm,18mm |

| Transport Package | Bag |

| Trademark | OEM |

| Origin | China |

| HS Code | 7019 |

| Production Capacity | 5000ton/Year |

Product Description

INTRODUCTIONChopped Strands are produced by cutting strand bundles, which are made of 50 to 200 fine ARG fiber filaments, into various length. It is used as reinforcement for Glassfiber Reinforced Concrete (GRC), Calcium Silicate and Slag Gypsum products. It is also used as crack control material for normal concrete and cement mortar. Its high alkali and acid resistance can be applied to glass fiber papers and filterChopped Strands are produced by cutting strand bundles, which are made of 50 to 200 fine ARG fiber filaments, into various length. It is used as reinforcement for Glassfiber Reinforced Concrete (GRC), Calcium Silicate and Slag Gypsum products. It is also used as crack control material for normal concrete and cement mortar. Its high alkali and acid resistance can be applied to glass fiber papers and filter

Item No. | Chop Length,mm | Features | Typical Application |

Leade-01 | 3,5,12,18 | Excellent dispersion and good mechanical properties of composite products | Reinforced gypsum |

Identification

Type of Glass | E6 |

Chopped Strands | CS |

Filament Diameter,μm | 16 |

Chop Length,mm | 12,18 |

Technical Parameters

Filament Diameter (%) | Moisture Content (%) | Size Content (%) | Chop length (mm) | Choppability (%) |

ISO1888 | ISO3344 | ISO1887 | Q/BH J0361 | Q/BH J0362 |

±10 | 10.0 ± 2.0 | 0.10 ± 0.05 | ±1.5 | ≥ 99 |

FOR BMC

Short Description:1.Secially designed for reinforcing unsaturated polyester, epoxy resin and phenolic resins.

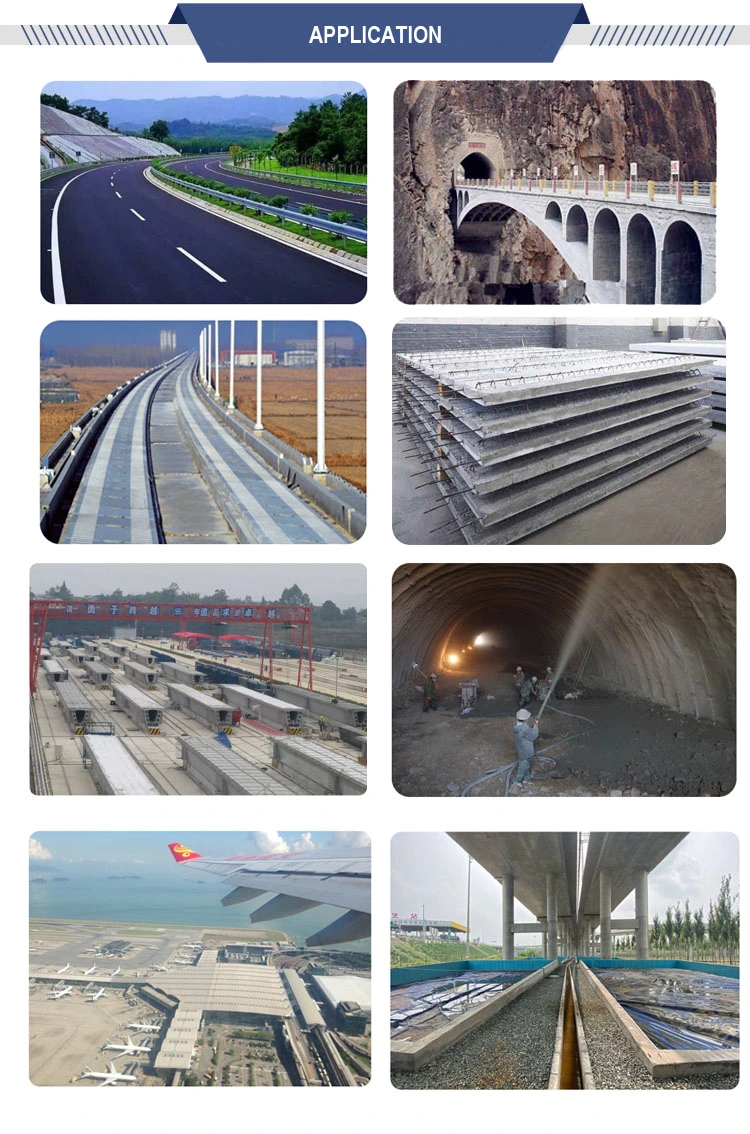

2.Widely used in transportation, construction, electronics,chemical industry and light industry. Such as the automotive parts, insulator and switch boxes.E-Glass Chopped Strands for BMC are specially designed for reinforcing unsaturated polyester, epoxy resin and phenolic resins.

Features

Good strand integrity

Low static and fuzz

Fast and uniform distribution in resins

Excellent mechanical and processing properties

BMC Process

A bulk molding compound is made by combining glass chopped strands, resin, filler, catalyst and other additives, This compound is processed by compression molding or injection molding to form the finished composite parts

A: Manufacturer, welcome to our factory

Q: What are your products?

A: Polypropylene fiber, Polyester fiber, polyacrylonitrile fiber, PVA fiber, plastic steel fiber, anti-crack fiber, wood fiber, cellulose fiber, glass fiber, Steel fiber, carbon fiber, colorful wall coating fiber, anti-rutting agent, PSBR high modulus asphalt additive, asphalt warm mix agent, asphalt flame retardant, asphalt modifier,Anti-stripping agent, Sun shading mesh

Q: Are the samples free?

A: Accept free sample test, buyer bear delivery charge

Q: How can we guarantee quality?

A: Always a pre-production sample before mass production;

Always final Inspection before shipment;

Q: What are your MOQ?

A: 1000KG Or More than 1000USD per order

Q: What is your delivery time?

A:Production will be arranged after receiving the deposit, and shipment will be arranged after all payments are made. The delivery time is about 10-15 working days.

Related Products

-

![High Quality Adhesive Soft Wool Sheet Polyester Non Woven Felt Fabric100% Recycle Polyester Felt for Mattress with Different Color Mix Cotton Polyester Recycle]()

High Quality Adhesive Soft Wool Sheet Polyester Non Woven Felt Fabric100% Recycle Polyester Felt for Mattress with Different Color Mix Cotton Polyester Recycle

-

![Epoxy Insulation Tube Epoxy G10 Fr4 Resin Pipe Epoxy Fiberglass Cloth Tube]()

Epoxy Insulation Tube Epoxy G10 Fr4 Resin Pipe Epoxy Fiberglass Cloth Tube

-

![Chopped Ar Glass Fiber for Reinforcing Render]()

Chopped Ar Glass Fiber for Reinforcing Render

-

![Refractory Twisted Fiberglass Rope for Thermal Insulation]()

Refractory Twisted Fiberglass Rope for Thermal Insulation