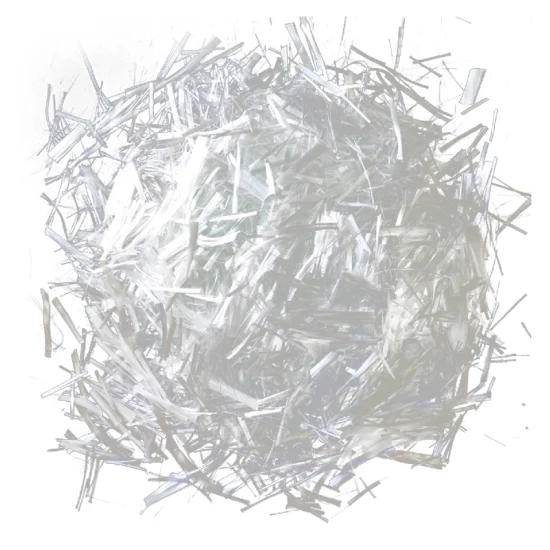

Strong Corrosion Resistance Ar Glass Fiber Chopped Strand for Concrete Reinforcement

Overview Package Size 25.00cm * 25.00cm * 25.00cm Package Gross Weight 25.200kg Strong Corrosion Resistance AR Glass Fib

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | AR Glass Fiber Chopped Strand |

| Breaking Strength (N/Tex) | 0.42 |

| Moisture Cotent(%) | <0.2 |

| Tensile Strength (Gn/M2) | 1.65 |

| Elastic Modulus (Gn/M2) | 75 |

| Stiffness (mm) | 120min |

| Soft Temperature | 860 |

| Specific Gravity (g/cm3) | 2.7 |

| Fire Resistance(Incombustilble) | Inorganic Material |

| Chopped Length(mm) | 36 |

| Zro2 | 16.7% Min |

| Transport Package | 20kg/Bag, 40bags/Pallet; 16t/20pallets/20gp |

| Specification | AR-GLASSFIBRE |

| Trademark | Briture |

| Origin | China |

| HS Code | 5503400000 |

| Production Capacity | 36000metric Ton/Year |

Packaging & Delivery

Package Size 25.00cm * 25.00cm * 25.00cm Package Gross Weight 25.200kgProduct Description

Strong Corrosion Resistance AR Glass Fiber Chopped Strand For Concrete Reinforcement

Product Description

AR fiberglass is the base material to make fiberglass reinforced cement(GRC), as a light, high strength incombustible, designable and easy shaped material, GRC has been widely used in building industry as board, corrugated roofing sheet, division panel.

AR Fibers have a huge advantage over other types of fiber by having a higher specific gravity. This means that the fiber will have about the same gravity of the sand, making the fibers stay away from the cement surface of the concrete. it has good flowability, good bundling, good dispersibility

Specification

| Material | AR-GLASSFIBRE |

| Zro2 | ≥16.7% |

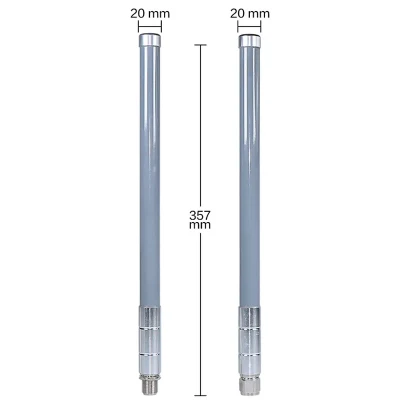

| Filament | 13±2μm |

| Liner weight of strand (TEX) | 76±10 |

| Specific gravity (g/cm³) | 2.7 |

| Chopped length (mm) | 36 |

| Fire resistance | Inorganic material |

| Moisture cotent(%) | <0.2 |

| Size content(%) | 1.8 |

| Soft temperature(ºC) | 860 |

| Stiffness(mm) | ≥120 |

| Tensile strength(GN/m2) | 1.65 |

| Elastic modulus(GN/m2) | 75 |

| Breaking strength(N/Tex) | 0.42 |

Characters

The 'Premix' production technique involves pouring or pumping a cement/fibre mix into a mould, similar to other precast production processes. The mix is compacted using vibration or by adding other components. The unit is left in mould to set and demoulded the following day.Pre-mix has the advantages that moulds can be simper to produce and strip.

Packing

20KG/bag, 40bags/pallet;16T/20pallets/20GP

Related Goods

PP Fiber Twisted Bunchy Form PP Macro Fiber Embossed Steel Fiber

Cocamide DEA Polyamide Hot Melt Adhesive Styrene Acrylic Copolymer Emulsion

Company Profile